Private label growth looks simple from the outside. Faster launches. Better margins. Full brand ownership. But in practice, private label manufacturing mistakes quietly derail more brands than market competition ever does.

Modern brands are increasingly adopting private label manufacturing as a growth model to introduce products quickly, manage pricing, and retain brand ownership without investing in large production facilities. From early-stage e-commerce founders to established retailers, private label products now sit at the core of competitive strategy across industries.

At Beaucience, private label manufacturing is not a service add-on. It is a system built through formulation discipline, supplier selection rigor, and documented quality control. What we see repeatedly is this: small oversights in these areas do not stay small. They compound into financial strain, regulatory exposure, and long-term brand credibility loss.

This article breaks down the most common private label manufacturing mistakes brands repeat, why they happen, and how to avoid them through better supplier selection, disciplined quality control, and informed decisions around custom formulations. The goal is simple. Build a scalable private label brand without compromising quality, trust, or long-term growth.

Also Read:

- Skincare Stability Testing Is Not Optional for Modern Beauty Brands

- Designing Scale-Ready Skincare from Day One

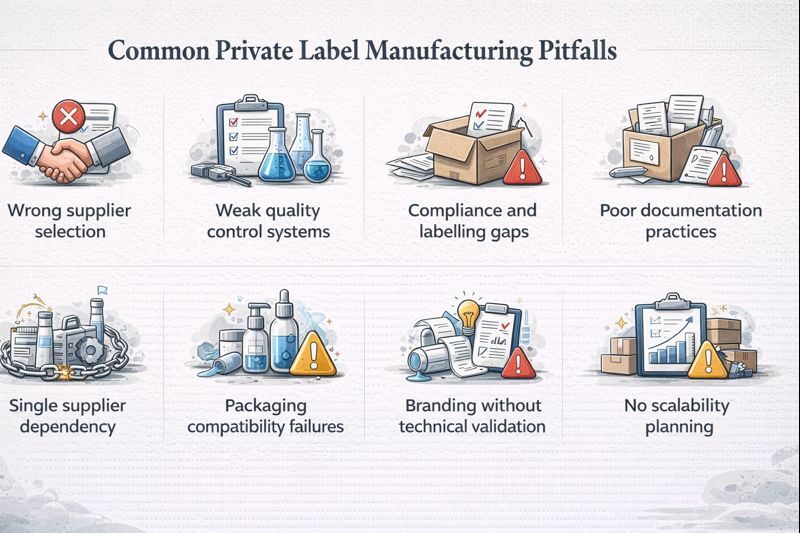

Supplier and Manufacturing Errors in Private Label Manufacturing

Supplier and manufacturing errors are among the most damaging private label manufacturing mistakes because they directly affect product quality, timelines, and regulatory safety. When brands underestimate supplier selection, early decisions create long-term operational risks that are difficult and expensive to correct later.

Choosing Cost Over Capability in Supplier Selection

One of the most common private label manufacturing errors occurs when brands prioritise low unit costs over supplier reliability, category experience, and operational maturity. Inadequate supplier selection often results in inconsistent batches, missed delivery timelines, and quality deviations that weaken private label products after launch.

Many brands also fail at basic due diligence. Certifications, production capacity, compliance history, and experience with similar custom formulations are either assumed or ignored. Without audits, pilot batches, or validation trials, these risks remain invisible until products reach the market, when corrective action becomes far more costly.

Communication Gaps and Operational Dependency Risks

Breakdowns in communication further amplify supplier-related risks in private label manufacturing. Unclear specifications, loosely defined timelines, and poor documentation lead to repeated production errors and accountability gaps. When brands depend on a single supplier with no backup plan, they become vulnerable to price changes, supply interruptions, and sudden compliance failures.

Common supplier-related traps include limited category experience, missing ISO or GMP certifications, single-source dependency, and incomplete documentation standards. Each of these weakens quality control and reduces a brand’s ability to scale with confidence.

Why Supplier Errors Create Long-Term Damage

Supplier misjudgement is not a short-term issue. It compounds over time, eroding margins, delaying growth, and increasing regulatory exposure. Strong supplier selection, disciplined documentation, and diversified sourcing are essential to avoid private label manufacturing mistakes and protect both brand credibility and long-term scalability.

Quality and Compliance Failures in Private Label Products

Quality and compliance failures are among the most underestimated private label manufacturing mistakes, yet they carry the highest long-term risk. Many brands assume suppliers will manage quality independently, without defining benchmarks, inspection checkpoints, or corrective systems. This absence of ownership weakens quality control from the very first batch.

When Quality Control Is Treated as an Afterthought

Weak quality control leads to inconsistent private label products, higher return rates, and negative consumer feedback. Over time, these issues erode customer confidence and damage brand credibility, especially in competitive categories where alternatives are easily available. Without clear specifications and validation processes, even well-formulated products can fail in execution.

Compliance failures compound the risk. Missing regulatory approvals, incorrect labelling, or incomplete ingredient disclosures can trigger recalls, penalties, or platform delisting. Unlike pricing errors, compliance lapses are difficult to recover from once trust is lost.

Why are quality and compliance failures harder to fix than other mistakes?

Because trust, once broken, cannot be corrected with quick changes. Quality and compliance failures signal systemic weakness, not isolated error, making recovery slow and reputational damage long lasting.

Common failures include the absence of defined quality benchmarks, lack of pre-shipment or in-process inspections, labelling inaccuracies across regions, and reactive problem-solving driven only by customer complaints.

Quality failures rarely stay contained. Over time, they escalate into legal exposure, margin loss, and brand dilution. Active quality control, regulatory discipline, and documented processes are essential to avoid private label manufacturing mistakes and protect long-term brand equity.

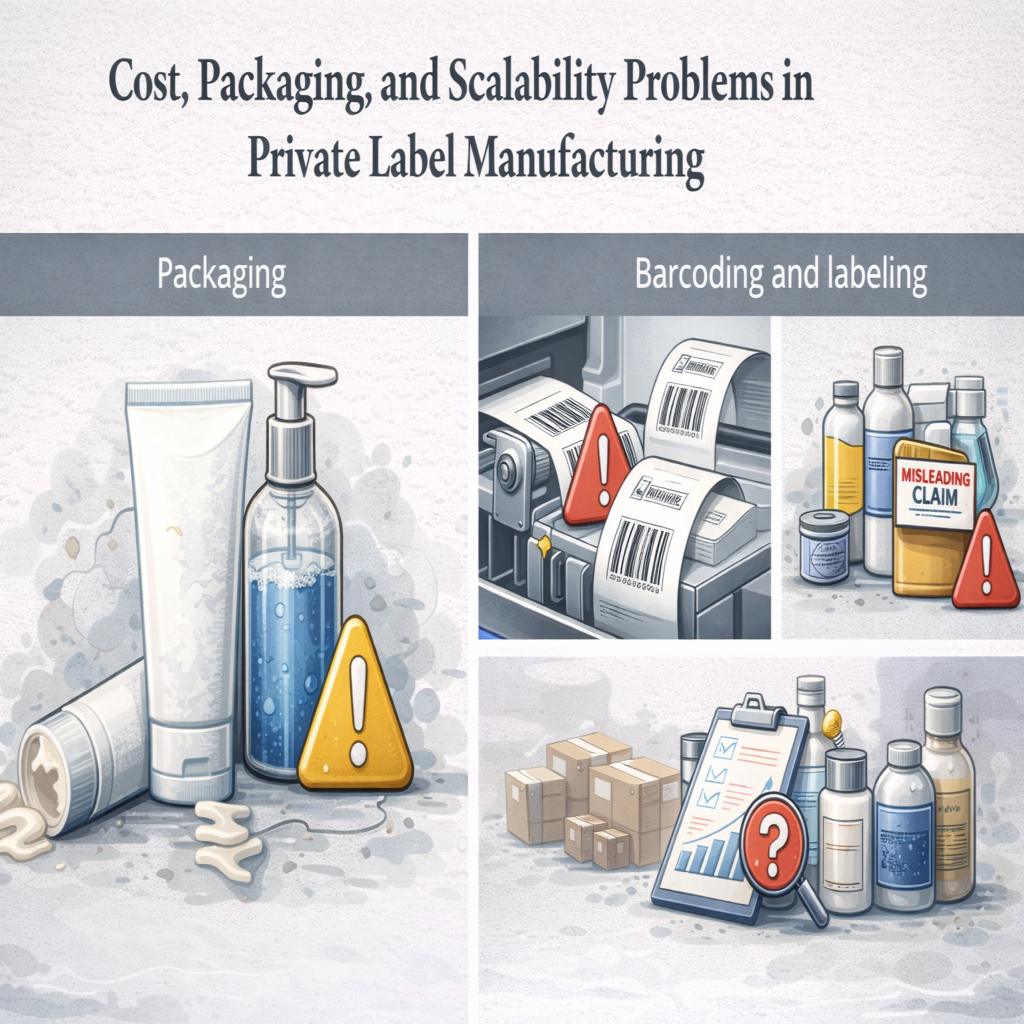

Cost, Packaging, and Scalability Problems in Private Label Manufacturing

Cost, packaging, and scalability issues often surface after launch, making them some of the most expensive private label manufacturing mistakes to correct. Many brands plan for production but underestimate how pricing models, packaging decisions, and growth readiness directly affect long-term margins and brand perception.

Hidden Cost Structures That Erode Margins

One of the most common cost-related errors in private label manufacturing is incomplete cost modelling. Brands frequently calculate profitability using only manufacturing costs while overlooking logistics, duties, warehousing, platform fees, and marketing expenses. As volumes grow, these hidden costs compress margins and limit reinvestment capacity.

Scalability further complicates cost control. When supplier pricing changes with volume or capacity is not planned in advance, unit economics become unstable. Without early alignment between demand forecasts and supplier capability, growth creates financial strain instead of efficiency.

Packaging Decisions That Limit Brand and Scale

Packaging is often treated as a visual choice rather than a strategic one. Generic or low-quality packaging weakens brand differentiation and reduces conversion, especially in crowded marketplaces. Packaging also impacts logistics, storage efficiency, and regulatory compliance, all of which influence scalability.

Poor packaging planning can delay restocks, increase damage rates, and restrict expansion into new channels or regions.

Cost, packaging, and scalability challenges are interconnected. When addressed early through realistic cost planning, strategic packaging design, and scale-ready supplier alignment, private label manufacturing becomes predictable, profitable, and resilient rather than reactive and fragile.

How to Escape Pitfalls in Private Label Manufacturing

Avoiding private label manufacturing mistakes requires system-led thinking rather than tactical fixes. Brands that scale successfully treat private label manufacturing as an operating discipline where supplier selection, quality control, and scalability planning are defined early and reviewed continuously.

Best practices that prevent private label manufacturing mistakes include:

- Supplier scorecards: Measure quality control outcomes, compliance history, pricing stability, and response discipline on an ongoing basis.

- Capability-led supplier selection: Evaluate certifications, category experience, production controls, and scale readiness beyond unit cost.

- Written operating guidelines: Define formulation, packaging, labelling, and documentation standards before production starts.

- Quality control points: Embed inspections at raw material intake, in-process stages, and pre-dispatch to prevent batch-level failure.

- Compliance alignment: Verify regulatory approvals, ingredient disclosures, and market-specific labelling before launch.

- Scalability planning: Match supplier capacity, inventory strategy, and demand forecasting to realistic growth timelines.

When these controls are missing, issues surface only after products reach consumers, where correction becomes expensive and credibility loss accelerates.

Private label success is built through planning, not reaction. Structured supplier selection, disciplined quality control, and scalability alignment convert private label manufacturing from a recurring risk into a reliable growth engine.

Also Read:

- CC Sunscreen Formulation Science: How Hybrid Sun Care Is Evolving

- Third Party Manufacturing 2026: The New Rules for Beauty Brands

Conclusion

Private label manufacturing offers significant growth potential, but only when guided by discipline and foresight. The most common private label manufacturing mistakes stem from supplier misalignment, weak quality control, branding mistakes, and poor scalability planning. These errors are rarely accidental. They are the result of short-term decision-making that prioritises speed over structure.

Brands that address private label manufacturing mistakes early protect margins, customer trust, and long-term brand value. Organised due diligence, strong quality control systems, and informed branding decisions transform private label manufacturing from a tactical shortcut into a durable business asset. Growth becomes predictable. Risk becomes manageable. Credibility compounds over time.

If you are planning to build or scale private label products, partner with Beaucience for structured manufacturing, disciplined quality control, and scalable private label solutions built for long-term growth.